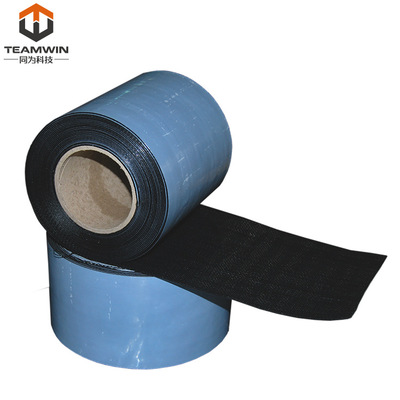

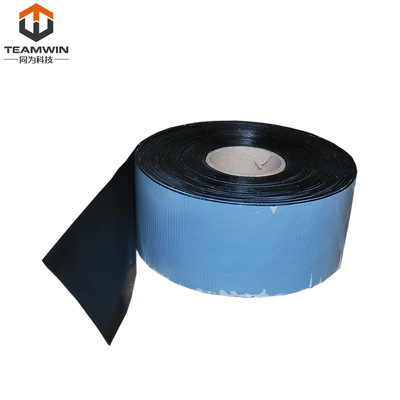

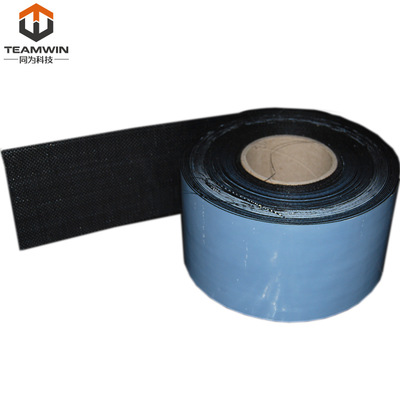

Construction: Three-layer system

Adhesives: Butyl rubber bituminous compound.

Backing: PP woven fabric cloth.

Interleaf: Anti-adhesive film treated with silicone

For corrosion protection of oil, gas, petrochemical, and waste water underground or overhead pipelines.

For waterproof:

•Cold applied.

•High resistance to bad weather environment

•Good performance itself to keep dry

•Easily application &installation

•Suitable for a wide range of temperatures

•Compatible primers

•Safe, clean

For pipes protection:

• Cold applied

• Excellent adhesion to pipe

• Flexibility provides extra protection at vulnerable areas

• Excellent conformability and consistent uniform thickness

• Easily applied with no special equipment

• Compatible with common pipe coatings

• Excellent resistance to cathodic disbonding

Product properties:

Backing colour | Black, yellow or others | ||

Inner wrap | T5100, T5130, T5150, T5165 | ||

Product Properties | Test Method | T5130 Typical Value | |

English | Metric | ||

Total thickness | ASTM D 1000 | 50.0 mil | 1.27 mm |

Width | - | 2’’- 39.5’’ | 50 -1000 mm |

Length | - | 33’’- 200’’ | 10-60 m |

Tensile strength | ASTM D 1000 | 35 lbs/in | 63 N/cm |

Peel Adhesion to primed interface | 296 oz/in | 33 N/cm | |

Cathodic disbandment | ASTM G8 | 0.25 in radius 6.4 mm | |

Dielectric strength | ASTM D 149 | 43KV | |

Volume Resistivity | ASTM D 257 | 2.5x1012 ohm.cm | |

Water Absorption | ASTM D 570 | 0.05% | |

Water Vapor Transmission Rate (24h) | ASTM E 96 | 0.01g/100sq in/24h | 0.1g/100sq mm/24h |

UV resistance | Excellent | ||

Application Temperature | 23℉-140℉ | -5 ℃ - 60 ℃ | |

Max Service Temperature | -4℉-176℉ | - 20 ℃ - 80℃ | |