• Heat shrinkage ratio: 2:1

• Environmental protection, high strength, elasticity, flame retardant

• Environmental standards:RoHS

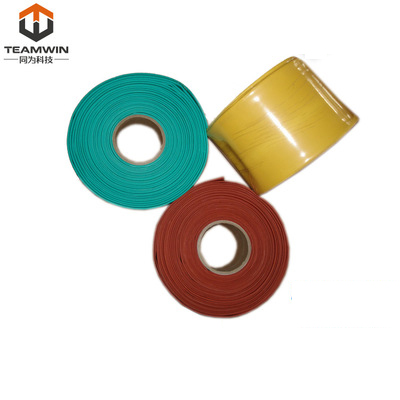

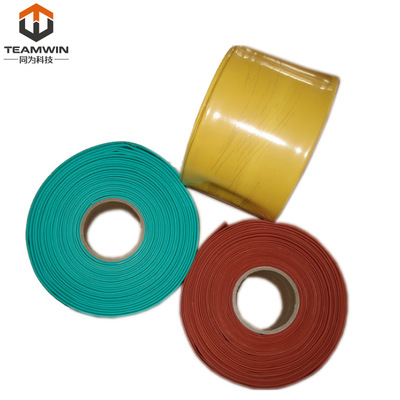

• Common colors: red, orange, yellow, blue, green, white, black

• Continuous use temperature: -55℃~125

• Minimum initial shrinkage temperature:84℃

• Minimum full shrinkage temperature:120℃

Technical data:

Performance | Typical Value | Test Method |

Tensile Strength | ≥8 Mpa | GB/T1040 |

Elongation at break | ≥300% | GB/T1040 |

Thermal aging tensile strength | ≥6.4 Mpa | GB/T1040,GB/T7141 |

Elongation at break after heat aging | ≥100% | GB/T1040,GB/T7141 |

Radial shrinkage rate | ≥50% | |

Axial change rate | Φ20~Φ30≤5%; | |

Thermal shock | No cracking, no flow | JB7829 D (160℃×4h) |

Low temperature resistance | No cracking | (<-40℃) |

Flame retardant | ≥28 | GB/T2406 |

Breakdown strength | ≥15kV/mm | GB/T1408.1 |

Volume resistivity | ≥4.3×1014Ω·cm | GB/T1410 |

Hardness (Shore A) | ≤90 | GB 2411 |

Specifications:

Type | Applied for Bus bar width (mm) | Diameter before shrink (mm) | Wall thickness after shrink (mm) | Diameter after shrink (mm) |

MPG-X-C-20/10 | 20-25 | ≥20 | 2.0±0.1 | <10 |

MPG-X-C-25/12 | 25-30 | ≥25 | 2.0±0.2 | <12 |

MPG-X-C-30/15 | 30-40 | ≥30 | 2.5±0.2 | <15 |

MPG-X-C-40/20 | 40-50 | ≥40 | 3.0±0.2 | <20 |

MPG-X-C-50/25 | 50-55 | ≥50 | 3.0±0.2 | <25 |

MPG-X-C-60/30 | 60-70 | ≥60 | 3.0±0.2 | <30 |

MPG-X-C-70/35 | 70-80 | ≥70 | 3.0±0.2 | <35 |

MPG-X-C-80/40 | 80-100 | ≥80 | 3.0±0.2 | <40 |

MPG-X-C-100/50 | 100-120 | ≥100 | 3.0±0.2 | <50 |

MPG-X-C-120/60 | 120-140 | ≥120 | 3.0±0.2 | <60 |

MPG-X-C-150/75 | 150-180 | ≥150 | 3.5±0.2 | <75 |

MPG-X-C-180/90 | 180-21 | ≥180 | 3.5±0.2 | <90 |

MPG-X-C-210/105 | 210-240 | ≥210 | 4.0±0.2 | <105 |

1. X denotation:1 (for 1kV), 10 (for 10kV), 35 (for 35KV). | ||||