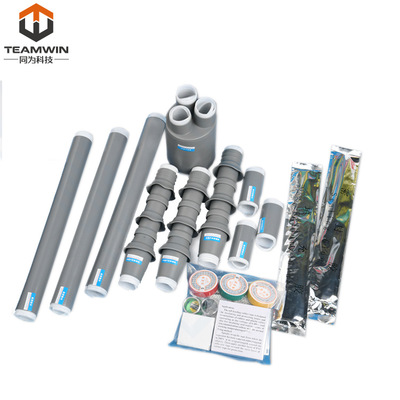

Cold-shrinkable cable accessories are injection-vulcanized in the factory using liquid silicone rubber, and are widely used in the terminal treatment of low-voltage cables; no hot fire and special tools are required. After installation, they always maintain a constant radial pressure on the cable body and have low partial discharge. The same "breathing" with the cable body.

Products are widely used in electric power, communications, military industry, metallurgy, coal mining, petrochemical and other fields.

● There is no need for fire and special tools, and no trouble of gradual insertion. As long as the core rope is gently extracted, it will rely on its own elasticity to retract, so as to cling to the cable. Each specification can be applied to multiple cables It has good compatibility with cable diameter.

● Using liquid silicone rubber, it has excellent insulation and high elasticity. After installation, it maintains a constant radial pressure on the cable body, which has low partial discharge and "breathes" with the cable body.

● Simple installation, low technical dependence on operation and easy to master. During cable pretreatment, the stripping distance is short and the installation space is small. The grounding method uses a constant force spring to fix the ground wire, without welding or copper binding, which is convenient, fast and reliable.

● Anti-fouling, aging resistance, good hydrophobicity, excellent corrosion resistance, cold resistance and UV resistance, and stable long-term performance. It is suitable for high altitude areas, cold areas, humid areas, salt fog areas and heavily polluted areas.

Specification of terminal:

Items | Test item | Standard requirement | Test result | Conclusion |

36KV indoor and outdoor terminals andintermediate connections | Power frequency withstand voltage | 105KV, 1min no flashover, no breakdown | 105KV, 1min no flashover, No breakdown | Qualified |

Partial discharge test | 39KV≤10pC | 39kv ,4PC | Qualified | |

Load cycle test, 3 cycles | When heating for 5h, cool for 3h. When heating, the conductor is heated at 95-100℃ and each cycle is 8h | When heating for 5h, cool for 3h. When heating, the conductor is heated at 95-100℃ and each cycle is 8h | Qualified | |

Partial voltage test | Discharge capacity at 39kv≤20pC | 39kv,4PC | Qualified | |

Impulse voltage test | 250kv, 10 times of positive and negative polarity, one flashover is allowed, but not counted in the total number of tests | 250kv, no flashover, no breakdown | Qualified | |

Negative polarity DC voltage test | 156KV, 15min no flashover, no breakdown | 156KV, 15min no flashover, no breakdown | Qualified | |

4h power frequency voltage test | 104KV, 4h no flashover, no breakdown | 104KV, 4h no flashover, no breakdown | Qualified |

Specification of splices:

Product name | Models | Applicable cable section (mm2) |

26/36KV one-core indoor terminal | TW-TLSY36-NLY/1.1 | 36-70 |

TW-TLSY36-NLY/1.2 | 95-150 | |

TW-TLSY36-NLY/1.3 | 185-300 | |

TW-TLSY36-NLY/1.4 | 400-500 | |

TW-TLSY36-NLY/1.5 | 630 | |

26/36KV one-core cold outdoor terminal | TW-TLSY36-WLY/1.1 | 25-50 |

TW-TLSY36-WLY/1.2 | 70-120 | |

TW-TLSY36-WLY/1.3 | 150-240 | |

TW-TLSY36-WLY/1.4 | 300-400 | |

TW-TLSY36-WLY/1.5 | 630 | |

26/36KV one-core splices | TW-JLSY36/1.1 | 25-50 |

TW-JLSY36/1.2 | 70-120 | |

TW-JLSY36/1.3 | 150-240 | |

TW-JLSY36/1.4 | 300-400 | |

TW-JLSY36/1.5 | 630 | |

26/36KV three-core indoor terminal | TW-TLSY36-NLY/3.1 | 25-50 |

TW-TLSY36-NLY/3.2 | 70-120 | |

TW-TLSY36-NLY/3.3 | 150-240 | |

TW-TLSY36-NLY/3.4 | 300-400 | |

TW-TLSY36-NLY/3.5 | 630 | |

26/36KV three-core cold outdoor terminal | TW-TLSY36-WLY/3.1 | 25-50 |

TW-TLSY36-WLY/3.2 | 70-120 | |

TW-TLSY36-WLY/3.3 | 150-240 | |

TW-TLSY36-WLY/3.4 | 300-400 | |

TW-TLSY36-WLY/3.5 | 630 | |

26/36KV three-core splices | TW-JLSY36/3.1 | 25-50 |

TW-JLSY36/3.2 | 70-120 | |

TW-JLSY36/3.3 | 150-240 | |

TW-JLSY36/3.4 | 300-400 | |

TW-JLSY36/3.5 | 630 |