Product description:For corrosion protection of oil, gas, petrochemical, and waste water underground or overhead pipelines.

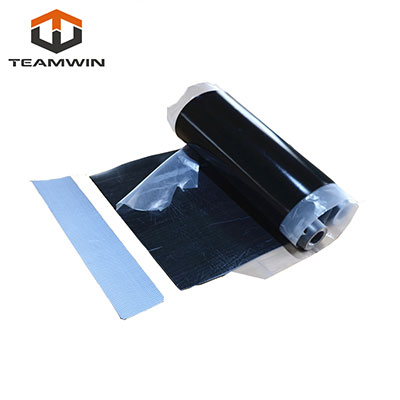

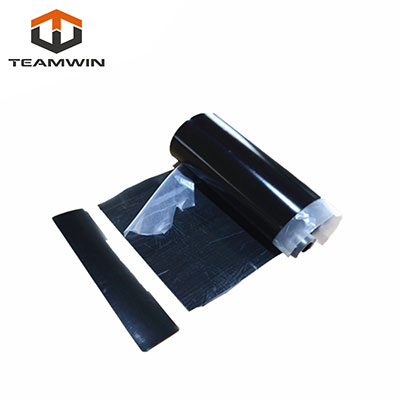

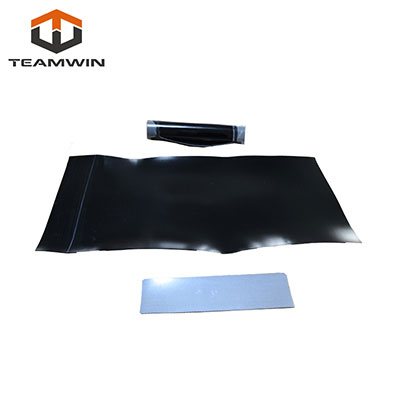

Construction: Three-layer system

First layer: Liquid epoxy, solvent-free two-component.

Second layer: High shear strength copolymer adhesive.

Third layer: Thick, fiberglass reinforced, radiation cross-linked polyethylene.

• Superior Force Cured Epoxy :Force cured epoxy cannot be displaced during the aligning and shrinking stages of the sleeve installation.

• Unique Adhesive Technology: Allows for lower installation pre-heat temperatures and superior bonding to PE, PP and FBE coatings.Adhesive has been formulated to bond directly to the main line coating

• Flexible Installation

• Long Term Corrosion Protection:Provides a protective coating with the structural integrity of a seamless tube, providing excellent resistance to cathodic disbondment and excellent durability against abrasion and chemical attack

• Saves Time & Money

Application:

Operating Characteristics | Test Method | Typical Values |

Pipeline Operating Temp | 70℃ | |

Minimum Installation Temp | 75℃ | |

Mainline Coating Compatibility | PE,FBE,PP |

Operating Characteristics | Test Method | Typical Values |

Pipeline Operating Temp | 80℃ | |

Minimum Installation Temp | 85℃ | |

Mainline Coating Compatibility | PE,FBE,PP |

Adhesive Properties | Test Method | Typical Values |

Softening Point | ASTM E28 | 113℃ |

Lap Shear @ 23°C | ASTM D1002-05 | 0.8 |

Adhesive Properties | Test Method | Typical Values |

Softening Point | ASTM E28 | 120℃ |

Lap Shear @ 23°C | ASTM D1002-05 | 1 |

Backing Properties

Tensile Strength | ASTM D638 | 19MPa |

Elongation | ASTM D638 | 550% |

Hardness | ASTM D2240 | 50Shore D |

Volume Resistivity | ASTM D257 | 4.0X1015 ohm-cm |

Tensile Strength | ASTM D638 | 24MPa |

Elongation | ASTM D638 | 550% |

Hardness | ASTM D2240 | 50Shore D |

Volume Resistivity | ASTM D257 | 4.0X1015 ohm-cm |

Sleeve Properties

Adhesion Strength @ 23°C | GB/T2792-98 | 140 N/cm |

Impact Resistance | GB/T2792-98 | Pass |

Indentation Resistance | ASTM D1000 | Pass |

Cathodic Disbondment @ 70°C, 30 days | ASTM D570 | 18 |

Low Temp. Flexibility | ASTM D2671C | >-30°C |

Nominal Size As Supplied

| Pipe Size | Pipe OD(mm) | Sleeve Length(mm) | Closure Width(mm | Backing / | |

DN(mm) | Inch (") | ||||

| 100 | 4 | 114 | 500 | 100 | ≥1.2/0.8 |

| 125 | 5 | 141 | 600 | 100 | ≥1.2/0.8 |

| 150 | 6 | 168 | 690 | 100 | ≥1.2/0.8 |

| 200 | 8 | 219 | 850 | 125 | ≥1.2/0.8 |

| 250 | 10 | 273 | 1040 | 125 | ≥1.2/0.8 |

| 300 | 12 | 324 | 1230 | 125 | ≥1.2/0.8 |

| 350 | 14 | 356 | 1340 | 125 | ≥1.2/0.8 |

| 400 | 16 | 406 | 1490 | 125 | ≥1.5/0.8 |

| 450 | 18 | 457 | 1660 | 125 | ≥1.5/0.8 |

| 500 | 20 | 508 | 1840 | 125 | ≥1.5/0.8 |

| 600 | 24 | 610 | 2180 | 150 | ≥1.5/0.8 |

| 700 | 28 | 711 | 2400 | 150 | ≥1.5/0.8 |

| 800 | 32 | 813 | 2750 | 150 | ≥1.5/0.8 |

| 900 | 36 | 914 | 3090 | 150 | ≥1.5/0.8 |

| 1000 | 40 | 1016 | 3430 | 200 | ≥1.5/0.8 |

| 1100 | 44 | 1120 | 3780 | 200 | ≥1.5/0.8 |

| 1200 | 48 | 1220 | 4120 | 200 | ≥1.5/0.8 |

| 1400 | 56 | 1420 | 4790 | 200 | ≥1.5/0.8 |

| 1500 | 60 | 1520 | 5130 | 200 | ≥1.5/0.8 |

| 1600 | 64 | 1620 | 5460 | 200 | ≥1.5/0.8 |

| 1700 | 68 | 1720 | 5800 | 200 | ≥1.5/0.8 |

| 1800 | 72 | 1820 | 6130 | 200 | ≥1.5/0.8 |

| 1900 | 76 | 1920 | 6470 | 200 | ≥1.5/0.8 |

| 2000 | 80 | 2020 | 6800 | 200 | ≥1.5/0.8 |

| 2200 | 88 | 2200 | 7410 | 200 | ≥1.5/0.8 |